Back-end Processing

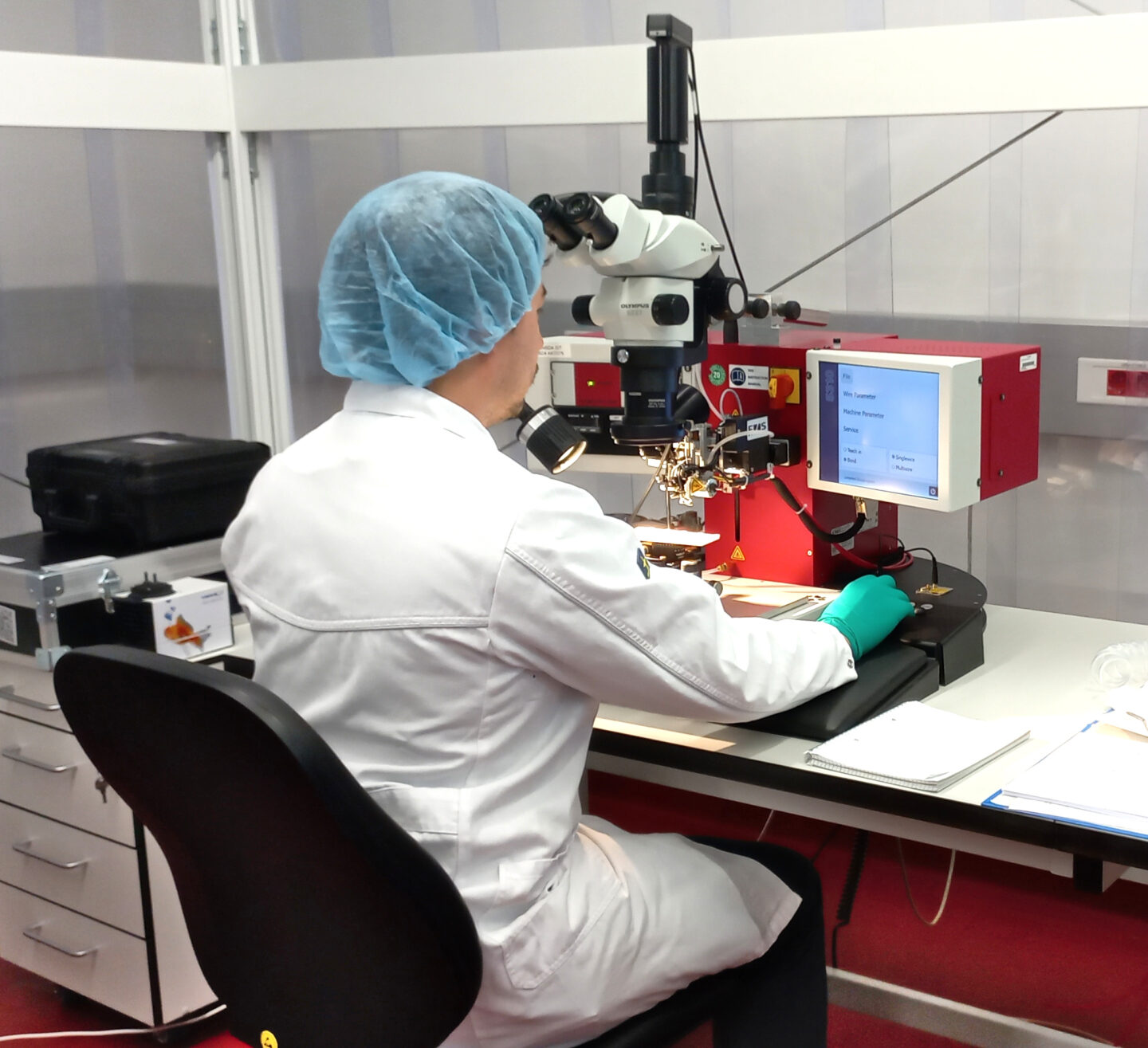

Wire bonder

5330 THIN WIRE WEDGE BONDER

The wire bonder 5330 can process aluminum and gold wires from 17.5 to 75 µm to 125µm width. Due to the mechanical manipulator system the operator can create different kind of loops. The bond head is equipped with automatic feed- and tail-function, which allows user-friendly bonding.

- DC motor driven Z-linear-axis

- Contactless electronic touchdown-sensor

- Generator 65 or 100kHz reversible programmable 0 up to 5W

- Bond force 15 up to 300cN – manually or electrically adjustable

- Clamp tear

- Substrate standard diameter 60 mm for components up to 2 x 2″

- Triangle, rectangular, reverse, stitch, programmable loops

Available wire: Aluminum

User Support and Scientific Advice:

Juan Luis Aguilera juan.aguilera@ist.ac.at

Rodolfo Previdi rodolfo.previdi@ist.ac.at

Evgeniia Volobueva evgeniia.volobueva@ist.ac.at

DIE BONDER

- Manual DIE-bonding with Touchdown-Detection and programmable

pickup- and bond force - 2 x 2“ working area for any Waffle-, Gel-Packs or Trays

- Bond- and pickup force from 5 up to 500 cN programmable

User Support and Scientific Advice:

Evgeniia Volobueva evgeniia.volobueva@ist.ac.at

Matko Kandzija matko.kandzija@ist.ac.at

Juan Luis Aguilera juan.aguilera@ist.ac.at

RTA oven

MILA-5000 MINI-LAMP ANNEALING SYSTEM

The MILA-5000 mini-lamp annealing system uses a heating sytem, in which an infrared (far-infrared) lamp is fixed at the focus of the paraboloidal reflector and reflects infrared beams in parallel. The lamp is available in two types: a near infrared lamp (100 V, 1 kW/piece) with high energy density that can heat the sample to a high temperature efficiently within a short time or a far-infrared lamp (100 V, 250 W/piece) suited to uniform heating. Being sealed in a quartz glass tube, these infrared lamps generates no gas from the heating element and allows clean heating. The furnace body is made of aluminum and is cooled with water to allow heating to a high temperature.

- Crystallization of annealing of thin ferroelectrics

- Rapid thermal annealing(RTA) of compound wafer

- Sintering of ohmic electodes

- Heating furnace for thin film deposition

- Substrate heating furnace in optical CVD

- Atmospheric annealing furnace

- Heat treatment in ultrahigh vacuum

- Heat resistance evaluation of surface coated film

- Thermal cycle test of heat resistant steels

- Characteristic evaluation of composite materials

- N2 and forming gas (5 % H2 in N2) are available

User Support and Scientific Advice:

Juan Luis Aguilera juan.aguilera@ist.ac.at

Bruno Magalhaes bmartins@ist.ac.at

Lubuna Shafeek lubuna.shafeek@ist.ac.at

Lapping and Polishing Equipment

Logitech PM6

The Logitech PM6 precision lapping and polishing equipment can be used for thinning down samples like Si, quartz, SiGe, ect. Current maximum sample dimensions are up to 20 x 20 mm.

Specifications: Sample dimensions up to 20 x 20 mm

Available lapping powder: Fused aluminium oxide – 5 μm and ultra fine aluminium oxide powder – 0.3 μm.

Polishing: Logitech SF1 polishing fluid. Alkaline Colloidal Silica, suitable for polishing wafers and a wide range of optical / optoelectronic components.

User Support and Scientific Advice:

Matko Kandzija matko.kandzija@ist.ac.at

Bruno Magalhaes bmartins@ist.ac.at

Salvatore Bagiante salvatore.bagiante@ist.ac.at

Dicing saw

Accretech SS10: SEMI-AUTOMATIC DICING SAW

SS10 dicing saw contains a high-speed spindle fitted with an extremely thin diamond blade to dice, cut, or groove semiconductor wafers, silicon, glass, ceramic, crystal, and many other types of material. The thickness of the blades varies by the type of material to be cutted, it is of about 20μm ~ 35μm is used when cutting the silicon wafer.

- Standard Spindles up to 60,000rpm

- Enhanced throughput

- X axis 600mm/sec, Y axis 160mm/sec, and Z axis 80mm/sec

- 17” LCD touch panel

- Kerf check function

- Stores over 10,000 recipes

- Optimized vacuum controller

User Support and Scientific Advice:

Rodolfo Previdi rodolfo.previdi@ist.ac.at

Juan Aguilera juan.aguilera@ist.ac.at

Bruno Magalhaes bmartins@ist.ac.at

Electro Polishing system

Microstrip

Microstrip electro polishing system removes metal and polishes the surfaces of precious and base metals and is suitable for electropolishing small samples.

User Support and Scientific Advice:

Lubuna Shafeek lubuna.shafeek@ist.ac.at

Rodolfo Previdi rodolfo.previdi@ist.ac.at

Evgeniia Volobueva evgeniia.volobueva@ist.ac.at